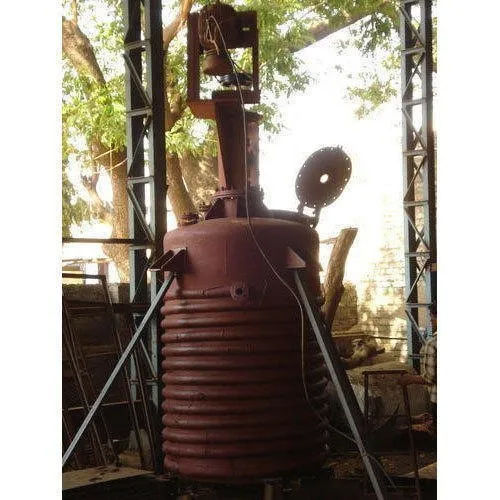

SS Cladding Reactor

SS Cladding Reactor Specification

- Product Type

- SS Cladding Reactor

- General Use

- Chemical Industry

- Material

- Stainless Steel

- Computerized

- No

- Drive Type

- Electric

- Color

- Gray

SS Cladding Reactor Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

About SS Cladding Reactor

- Composite structure:The reactor uses a base material, often carbon steel, and overlays it with a layer of stainless steel. This creates a composite material with unique properties.

- Corrosion resistance:The stainless steel cladding protects the inner vessel from corrosion, which is a key advantage in environments where the base material would be susceptible to rust or chemical degradation.

- Hygiene and finish:In industries like pharmaceuticals, the outer stainless steel cladding can be polished to a smooth, sanitary finish, making it easy to clean and disinfect, and is often used for GMP (Good Manufacturing Practice) compliant equipment..

- Structural integrity:The base material provides the necessary strength to withstand high pressures and temperatures, while the stainless steel cladding provides protection against corrosion and other damaging elements.

- Application-specific:The specific design and materials are chosen based on the intended use. For example, a reactor for a chemical plant will have different specifications than a nuclear reactor, where stainless steel may be used for fuel cladding.

- Chemical and pharmaceutical:Used for processes like synthesis, polymerization, and hydrogenation, with the hygienic finish being crucial for drug manufacturing.

- Nuclear:Stainless steel was historically used as a cladding for nuclear fuel rods in pressurized water reactors, and is being re-evaluated for use in certain accident scenarios due to its resistance to hydrogen production.

- Industrial:Can be used for a wide variety of other chemical processes that require a corrosion-resistant and strong vessel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Reactor Category

Stainless Steel Limpet Coil Reactor

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Product Type : Stainless Steel Limpet Coil Reactor

General Use : Industrial

Material : Stainless Steel

Mild Steel Chemical Reactor

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Product Type : Chemical Reactor

General Use : Industrial

Limpet Coil Mixing Tank

Price 175000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Product Type : Limpet Coil Mixing Tank

General Use : Industrial

Material : Stainless Steel

Jacketd SS Reactor

Price 300000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Product Type : Jacketd SS Reactor

General Use : Chemical Industry

Material : Stainless Steel

|

S N ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |